Exploring for New Understanding is a Joy of Life

February 17, 2022

Sensmet Showing the Way – Record Sensitivity in Online Municipal Wastewater Measurement

July 6, 2022

Author

There is a massively growing global demand for lithium-ion batteries due to the sales surge of electric vehicles. However, there is a downside as the ever-increasing amount of battery waste needs to be managed accordingly. New recycling processes are being vigorously developed, and new recycling plants are planned.

Reliable measurements are essential to run any production process efficiently: you must measure to control and optimise. In battery recycling, measurement technology plays even more crucial role: the quality of measurements directly affects the quality of the recycled battery metals.

Knowing correct information at the right time gives you the competitive edge. Conventional ICP-OES is a great analytical tool and the workhorse of the industry. A fact is, however, that off-line laboratory results are always late.

Online analysis of metal concentrations in process fluids and aqueous mineral solutions

Online analysis of metal concentrations in process fluids and aqueous mineral solutions has been a hard nut to crack in the past.

Sensmet µDOES® is a high-performance plasma-based OES, designed for online measurement. The ICP-OES technology principles have been rethinked to achieve the robustness required for the continuous and fully automated measurement. Real-time monitoring of metals in various battery recycling processes is now possible.

Instant analysis results are precious for process control. It is also easier to estimate the process yield and quality when one knows the elements along the production lines in real-time.

Limitations of ICP – it’s so laborious

Lithium production and battery recycling is an industry that runs a massive number of elemental analyses using conventional ICP-OES. Sometimes the analytical facilities are distant, and the associated sampling and logistics become a costly challenge.

Naturally, in modern facilities, auto-samplers are installed next to the process. However, even with nice auto-sampling, ICP machines are still located in the laboratory, and staff is needed to do sample pre-treatment work.

Sensmet µDOES® multi-metal analyser technology is fully automated. It helps to save labour and reduce errors related to manual sample preparation.

Analysis of alkaline and alkaline earth metals – lithium and sodium as an example

Alkaline and alkaline earth metals may interfere with each other in conventional ICP-OES analysis. There are limitations to getting accurate values using ICP-OES – we have even heard customers doing calibrations every time making the analysis. Other customers say they need to apply AAS.

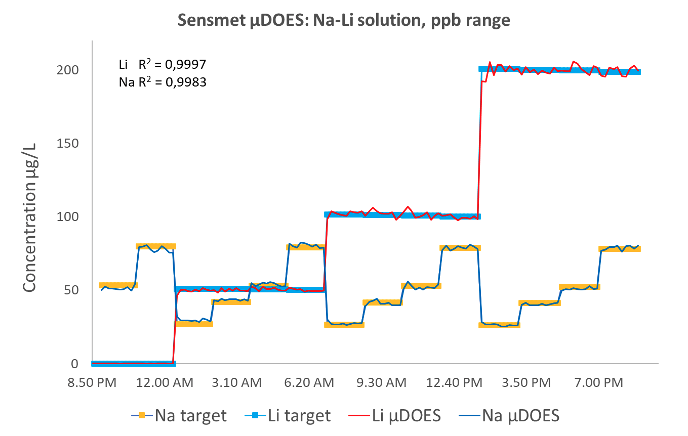

In April 2022, our customer asked: “Can you measure varying lithium and sodium concentrations online, at µg/L concentration without adding any internal standard to the sample?” We made the calibration (Figure 1), and already in June, Sensmet will run production tests at the customer site.

What makes Sensmet µDOES® so well suited for online measurements of lithium, sodium, cobalt, manganese, and nickel?

The following product properties make µDOES® so robust in battery metal analysis:

- Carrier gas free operation

- ICP: The carrier gas is often a significant cost factor for ICP users

- µDOES®: Produces the plasma directly inside the liquid; there is no need for any carrier gas

- Free from nebuliser issues

- ICP: Nebuliser clogging, salt formation or precision problems can be nerving for ICP users

- µDOES®: Free from nebuliser problems as there is no need for such a component

- No more spray chamber challenges

- ICP: Users often discuss how to prevent large droplets from reaching the ICP torch or reduce the solvent load and improve plasma stability

- µDOES®: Produces the plasma directly inside the liquid. Spray chamber maintenance has no relevance as there is no need for such a component

- Torch free operation

- ICP: Users report issues such as torch misalignment, oxidisation of interface cones, or RF coil corrosion

- µDOES®: Unique plasma-based OES without a torch, RF coil, and cones – thus free from daily issues related to such standard ICP-OES problems

- An internal standard is not a necessity – we like to optimise maintenance of online instrumentation

- ICP: To reach adequate accuracy, ICP users often need to use internal standards to correct for matrix differences between the calibration standards and samples

- µDOES®: Online analyser designed to deliver quantitative results for process control. In principle, the effects of the sample matrix are modelled directly in the calibration curve. Consequently, internal standard is avoided in most applications.

- Ease of use

- Sensmet’s µDOES® design philosophy is “Press the button and get the results!” The µDOES® instrument provides continuous operation year after year.

Aappo Roos, Chief Sales Officer