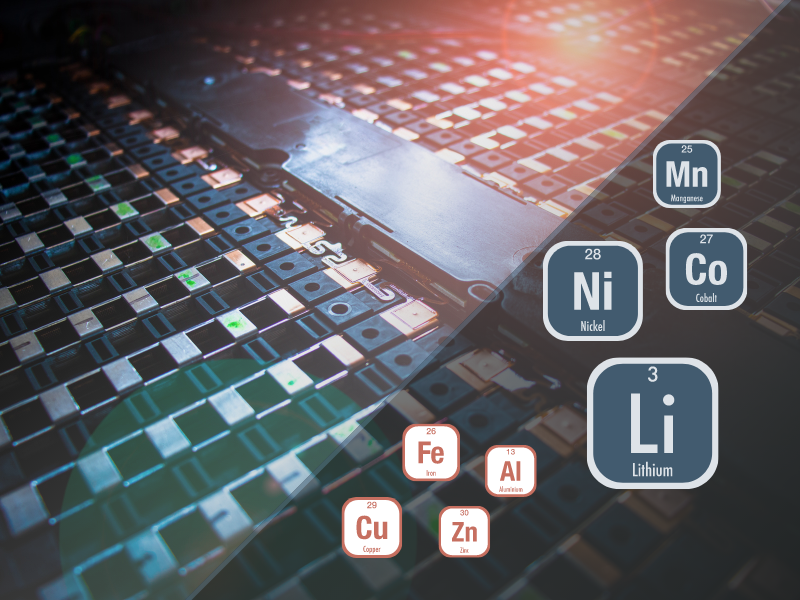

Black Mass Recycling

of Li-Ion Batteries

Optimise Black Mass Recycling of Li-Ion batteries with our revolutionary measurement technology. Monitor and control the hydrometallurgical extraction of Ni, Co, Mn, and Li in real time, ensuring precise metal recovery and impurity management.

Battery Metals and

Alkali Production

Enhance and optimise the measurement of battery metals and alkali production with our advanced technology. Monitor and control lithium production, wastewater management, and potash processing to ensure precise and efficient operations.

Online monitoring of metal concentrations allows improved battery recycling and manufacturing processes

Sensmet’s µDOES® real-time analysis and process control technology for battery metal recycling and manufacturing will significantly improve the efficiency of modern fast hydrometallurgical processes. This increases productivity and reduces waste, whilst also helping to ensure end-product quality and purity.

µDOES® technology covers 30 metals in industrial process and environmental waters

Automated 24/7 real-time analysis of metal concentrations without expensive carrier gas and chemical reagents

Robust and field-proven for industrial measurements

Unique Features

Sensmet's patented μDOES® (Micro-discharge Optical Emission Spectroscopy) technology offers a unique combination of benefits for real-time process monitoring and control:

Continuous, real-time measurement

100% automated system with extended maintenance intervals

High analytical performance

Suitable for real-time analysis of light-weight elements such as lithium, sodium, magnesium and potassium which pose a challenge for many other methods

Low cost of ownership as no carrier gas no chemical reagents are required

Green chemistry